We follow a strict quality-controlled procedure to ensure consistent and reliable results:

-

Pre-treatment: Thorough degreasing and pickling to clean the surface

-

Electroplating: Controlled zinc deposition via electrolysis

-

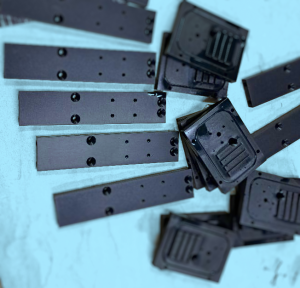

Passivation: Application of blue or black chromate for enhanced protection

-

Optional Sealing: Added topcoat or sealant for extended corrosion life

-

Inspection & Quality Control: Every part is carefully checked before delivery

✅ Why Choose Us?

-

ISO 9001:2015 Certified Quality Management System

-

Experienced, certified engineers and skilled technicians

-

Environmentally responsible plating solutions

-

Fast turnaround and consistent finish quality

📞 Contact us today to learn how our zinc plating services can protect and enhance your components.